The choice of the tire along with the correct wheel or caster is crucially important. The caster should be chosen knowing the required load capacity, the application and environmental conditions.

The chemical resistance of tires depends on the temperature and period of contact with the medium. Contact for a short period of time usually does not have a negative effect. Solid rubber tires normally demonstrate good resistance to water, diluted bleach and acids. Topthane® usually demonstrates good chemical resistance to grease, oil, aliphatic hydrocarbons and many solvents. It is not resistant to hot water, steam, acids and some alkalines. On request a list chemical resistance for tires is available.

A) Storage

Tires shoould be stored in a dry, cool place and be protected from direct sunlight. Storage

time should not exceed more than two years although polymide wheels can be

stored for a longer period under proper conditions.

B) Conditions of applications

The quality of the tires as well as the wheel diameter are determined by the nature of the

road surface. For example, it is preferable to choose a large wheel diameter with elastic

tires for use on an uneven surface.

The load capacity for the wheel or caster may be determined as follows: gross weight (=weight for vehicle + load) divided by 3. (in general, only three of the four wheels are in contact with a rough surface). Moreover temporary overloading can occur (for example when obstacles are encountered). More severe conditions may require a higher margin of safety.

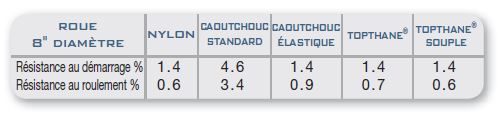

The rolling and start-up resistance are important factors for determining factors required for the movement of vehicle. resistance depends on the tires, temperature, fl oor surface and the total load. For example, on a smooth road surface and a wheel diameter of 200mm:

The choice of bearing depends on the conditions under which the wheel or caster is to be used and the intensity of use. Wheel bearings can be divided into the following groups:

- Plain bearings

Simple, almost maintenance free bearing. Resistant to shocks. Suitable for use in wet

conditions. For low speed vehicles.

- Roller bearings

Sturdy, resistant, almost maintenance free bearing. low friction bearing. Shock resistant.

The bearing most often used on low speed vehicles.

- Groove ball bearings (precision ball bearings)

Roll well even at higher loads and speeds and are suitable for continuous use.

- Tapered roller bearing

Used on heavy duty wheels. High load capacity. Variable movement.

The coeffi cient of friction is important for powered or braked wheels. The coeffi cient of friction depends on various factors such as the type of surface, humidity, dust, grease, the tire material and so on. Experience has shown that the coeffi ent of friction vary according to changes in the various factors. For example, a topthane® tire can rub a rolled steel surface or a rough concrete surface. The coeffi cient of friction indicates the relationship between horizontal force and vertical load. (Example: 10 000 newton vertical load, tire with u = 1 requires engine power of 10 000 newtons). The following fi gures are approximate:

The degree to which tires retain their shape under loads is called resilience and contribute to the driving comfort. Factors include the hardness and thickness of the tire. The resilience diagram does not proceed linear but degressive. On a smooth and hard road surface, the resilience would be measured as follows (having wheel 200mm diameter and bearing a nominal load):

After a period of time with static load fl ats may occur to the tyre - so called compression set. The compression set is a function of tyre material, load, resilliance, temperature and time. When the wheel is moved again, these fl ats are reversed and the wheel returns to normal after a short working period.

The degree of contact on the ground depends on resilience. The load divided by the surface contact indicate the static pressure of a wheel to the ground. Measured on a hard smooth surface with a wheel diameter of 200 mm, the pressure (N/mm2) amounts to: